- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

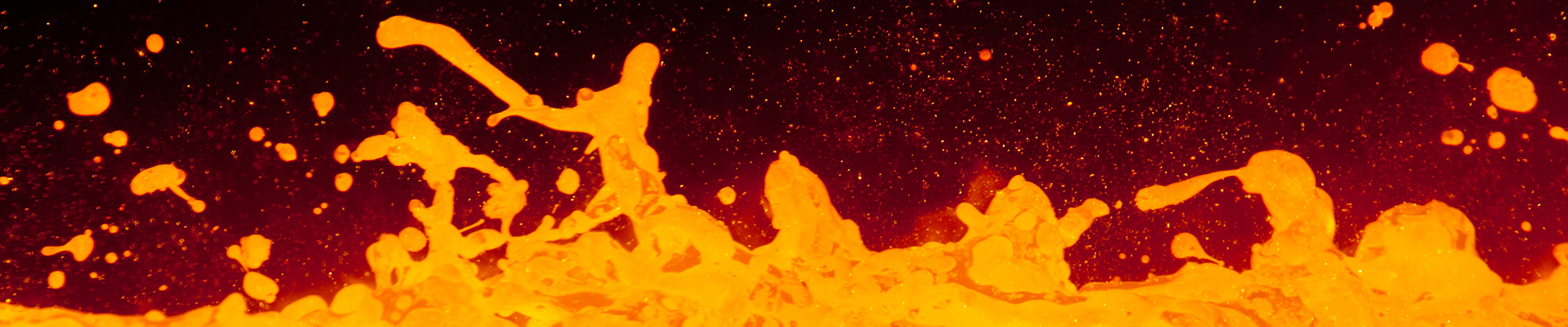

Direct Reduction

- Technology

- Direct Reduction

THE WORLD’S LARGEST MULTI-PRODUCT DRI PLANTS

Paul Wurth took an important step towards becoming a complete supplier of all iron and steel production processes in 2014 when it signed a construction license agreement with Kobe Steel in Japan. As a result, Paul Wurth is able to offer Midrex® gas-based direct reduction ironmaking plants as part of its portfolio.

High-performance applications

to meet various industrial needsSince then, Paul Wurth and its technology partner, Midrex Technologies, have completed and commissioned their first joint reference plants on behalf of Tosyali Holding in Algeria and Algerian Qatari Steel. Both Midrex® plants are designed to produce 2.5 million tonnes of hot and/or cold direct reduced iron per year, being the largest multi-product DRI plants in the world.

The Midrex® direct reduction process is the industry’s most productive technology for making high-quality direct reduced iron (DRI) products, accounting for approximately 60% of the world’s total annual production. DRI and its derivatives, including hot briquetted iron (HBI), are virgin iron feedstock used in steelmaking applications.

High-performance applications to meet various industrial needs:

Midrex NG™ is the configuration of the Midrex® process using natural gas, considered as the cleanest ironmaking fuel. Through use of the patented Midrex® Reformer, this technology produces, in a cost effective way, reducing gas for the iron ore reduction reactions that take place in the Midrex® shaft furnace.

MXCOL® uses syngas, or synthesis gas, from the cokemaking or coal gasification process, to produce DRI in the Midrex® process.

For more information, please visit the website of Midrex Technologies Inc.

Direct Ironmaking Technologies are also playing an important role when it comes to develop innovative, disruptive solutions for reducing CO2 emissions and producing “Green Steen”. Today already, the route combining NG based Midrex® technology and EAF generates the lowest CO2 emissions of any commercially proven steelmaking route. The shift towards H2-based, carbon-free DRI production would be an essential step towards Green Steel.

OUR MIDREX REFERENCES

Tosyali Algeria

Algerian Qatari Steel Related News

-

AQS Begins DRI Production in Algeria

More information -

World’s Largest HDRI/CDRI Plant Completes Construction in Algeria

More information

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2025 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking