- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

Blast Furnace Ironmaking

- Technology

- Blast Furnace Ironmaking

150 years of pioneering

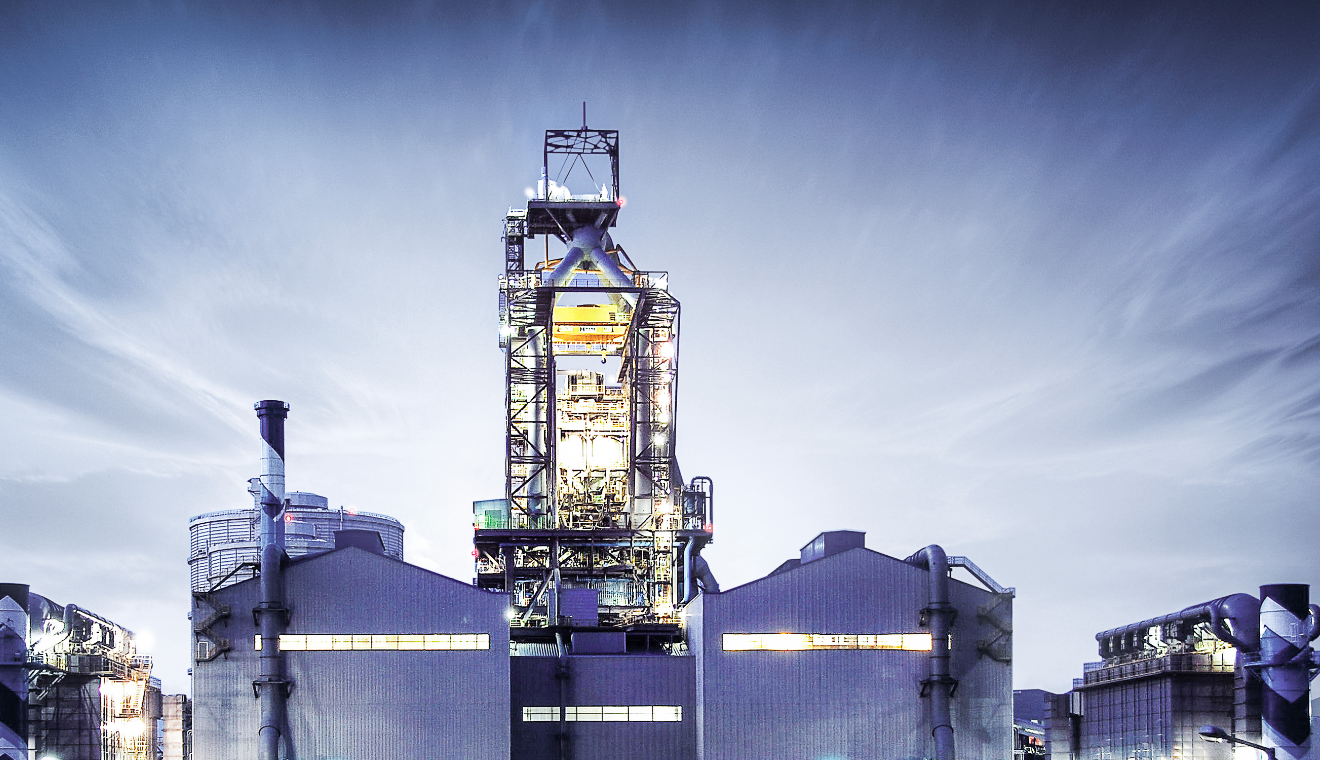

It all started with an opportunity. The main industrial opportunity of the outgoing 19th century: steel. The company started as a boilermaker facility and became very good at its craft. Paul Wurth had the far sight and made the shop seizing the opportunity by starting to diversify its activities. A new lever of success developed through improving existing processes and innovating by designing and launching new products and services. That is how we got in.

Today, our history is marked by more than 100 years of involvement in ironmaking facilities. We have been integrated blast furnace plant builders for almost 70 years now.

Like no other in this field, we have added to that much more: knowledge and competence in raw materials, in process technology and operations, control and automation, in aspects of upstream and downstream processes, in environmental and emission control.

Continuous improvement and decades of R&D activities created innovative solutions that aim at safety, quality, sustainability and customer benefit.

This journey continues with the unique and complete line of solutions, technology and equipment for blast furnace ironmaking being at home under one roof – at Paul Wurth.

Our Blast Furnace technology solutions

-

Modern Blast Furnace Design

Read moreOur profile, cooling & lining concepts, complemented by high-efficient cooling elements and refractories, ensure optimum campaign duration.

-

Top Charging

Read moreOffering comprehensive stockhouse, charging & related control technology, our charging philosophy always fits to your specific needs.

-

Hot Blast Generation & Supply

Read moreOur Hot Blast Stove solutions, coupled with heat recovery and blowers / TRT, ensure reliable operation and energy savings.

-

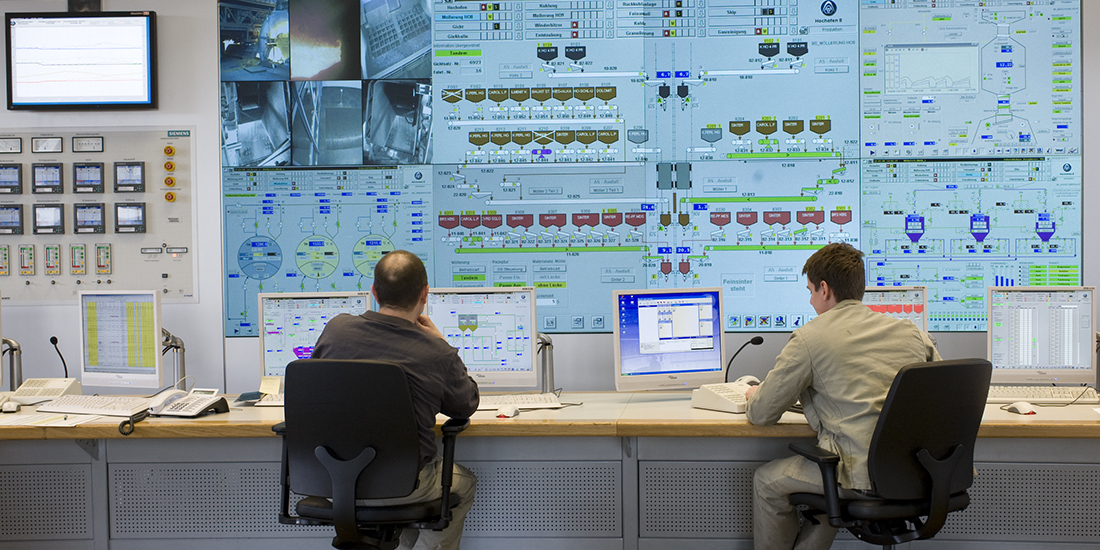

Process Control

Read moreA whole array of process control features (Probes, L1, L2, AI) make your process smart.

-

Tapping

Read moreOur casthouse design, fitted with corresponding machines, makes your casthouse operations safe and your hot metal supply stable.

-

Pulverised Coal Injection

Read moreOur proven PCI technology positively impacts your hot metal cost, CO2 balance and coke savings.

-

BF Top Gas Cleaning

Read moreOur gas cleaning systems stand for environmental protection, residues reduction, materials efficiency and optimal CO2 balance.

-

Slag Granulation

Read moreOur INBA system with steam condensation is officially recognised as a Best Available Technology.

Competences

Our products and services cover the full range of blast furnace projects ranging from complete new ironmaking plants, furnace modernisations and relines, new or upgraded equipment and systems, plant automation and process control systems, engineering design services through to equipment maintenance and spare parts. We provide operational and system design advice and on-site services for blast furnace operation and maintenance activities.

-

BF PLANT INTEGRATION & CIRCULAR ECONOMY

More informationIn our BF projects, we adopt a holistic approach, integrating Best Available Technology and Circular Economy principles.

-

BF PLANT CONSTRUCTION

More informationFrom design to blow-in of a new BF, Paul Wurth brings in its expertise at each stage of the project.

-

BF RELINE & MODERNISATION

More informationWe offer comprehensive and tailor-made reline strategies to make your modernisation project a success.

-

BF OPERATIONS SUPPORT

More informationThanks to our deep understanding of the BF process, we are able to provide proficiency support and expert solutions to BF operators.

Shaping the future of ironmaking

Related Brochures

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2024 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking