- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

News

23rd October 2019

Třinecké Železárny awards blast furnace hearth reline to Paul Wurth

Třinecké Železárny, a.s., an integrated steel works located in the very North-East of the Czech Republic in the town of Třinec, produces added value products such rails, sections, steel wire and bar, seamless tubes as well as special steel for tools and springs. The whole production bases on an ironmaking plant consisting of two blast furnaces of nearly equal design, with a joint capacity of just a little bit more than 2 million tons of hot metal per year.

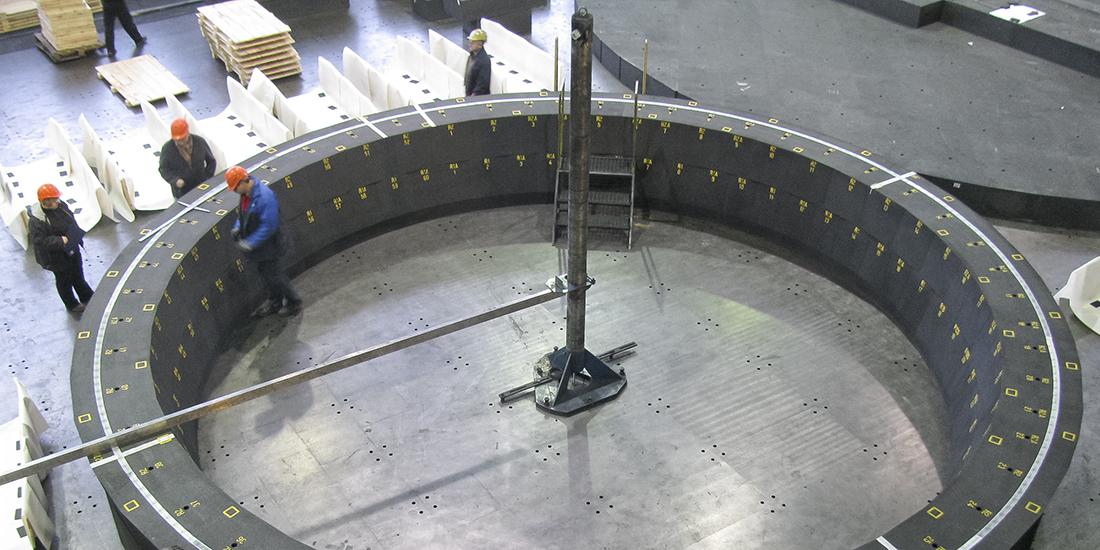

In late spring 2019, Třinecké Železarny has awarded a contract to the Paul Wurth group for the complete reline of No.6 blast furnace’s hearth.

The project includes basic and detail engineering for the new hearth and the supply of all refractory materials. On top of the refractory engineering and deliveries, Paul Wurth will be responsible for all site activities such as salamander tapping, removal of residual hot solid material, demolition of the old hearth, assembly of the new hearth as well as the corresponding site management and supervision.

Already in the offer phase, Paul Wurth has advised Třinecké Železárny over a longer period on possible campaign extension measures and reline techniques. This included assessment of the status of No. 6 BF’s hearth by application of multipoint thermocouple sensor probes (MTP probes) installed in two steps in 2017 and 2018.

The upcoming reline of the hearth of BF6 is a result of trustful consultation and partnership between Paul Wurth and the customer in choosing the appropriate reline strategy for this ironmaking plant. In this context, it is also worth to look back into history: the currently installed hearth of this furnace has been designed by engineers of DIDIER/DME – today known as Paul Wurth’s refractory engineering division in Wiesbaden. This hearth has been in operation for more than 20 years by now and will reach a campaign of 22 years when the reline will start in 2021.

About Paul Wurth

Headquartered in Luxembourg since its creation in 1870, the Paul Wurth Group is an established technology provider for the primary stage of integrated steelmaking. Paul Wurth is a leading market player for the design and construction of complete blast furnace and coke oven plants. Direct reduction plants, environmental protection solutions and recycling technologies complete Paul Wurth’s product portfolio. With more than 1 500 employees and entities in around 20 countries, the Paul Wurth Group has a strong presence in the significant iron and steel regions of the world.

PAUL WURTH S.A. ● 32, rue d’Alsace ● P.O. Box 2233 ● L-1022 Luxembourg

Tel.: (+352) 4970-1 ● paulwurth@paulwurth.com ● www.paulwurth.com

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2024 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking